What Happens to Depleted EV Batteries – Are They Really Recycled? (2025 Guide)

Electric vehicles are rapidly becoming the global standard for sustainable transportation. But as EV adoption accelerates, a crucial question keeps surfacing:

What actually happens to used EV batteries—and are manufacturers truly recycling them?

In 2025, the conversation around EV battery recycling is louder than ever. Drivers want transparency. Regulators want proper waste management. And environmentally conscious buyers want reassurance that EVs are not secretly creating a new pollution crisis.

This article breaks down the real state of EV battery recycling: the process, the companies leading the charge, the ethics behind second-life repurposing, and what to expect in the coming years.

Why the Recycling Conversation Is Still So Unclear

Many automakers communicate the recycling process vaguely, often citing regulations or technological limitations as reasons for limited disclosure. Battery manufacturing is a competitive field, and companies treat recycling innovations as trade secrets.

As a result:

- Consumers rarely receive clear information on what happens to their used batteries

- Manufacturers focus on marketing “sustainability” rather than specific data

- Recycling rates vary significantly by region and company

However, new laws in the EU, US, and Asia are pushing for stricter reporting and mandatory recovery rates for key materials like lithium, cobalt, nickel, and manganese.

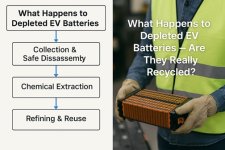

How EV Battery Recycling Actually Works in 2025

Recycling an EV battery is a multi-step industrial process. Here’s the simplified version:

1. Collection & Safe Disassembly

Batteries are collected from service centers, scrapyards, and repair shops. Damaged packs require special handling to avoid thermal runaway.

2. Shredding & Material Separation

The battery is shredded into small fragments. Advanced systems separate components into streams:

- Metals (copper, aluminum, nickel, cobalt)

- Plastics

- Black mass – a powder containing lithium, manganese, nickel, cobalt

3. Chemical Extraction (Hydrometallurgy)

This step dissolves the black mass and recovers critical minerals. Hydrometallurgical methods are now preferred because they have:

- Higher recovery rates

- Lower emissions

- Lower energy consumption

4. Refining & Reuse

Recovered materials are turned back into battery-grade feedstock, closing the loop in the supply chain.

Are EV Batteries Really Recycled?

Yes-but not always immediately and not everywhere.

The global recycling industry is growing rapidly, but capacity still lags behind the number of EVs on the road.

The good news:

Most EV batteries don’t go straight to recycling. Instead, they enter second-life applications.

Second-Life Batteries: The Fastest-Growing Trend in 2025

Even when an EV battery drops below 70–80% capacity (unsuitable for cars), it still has years of life left for other uses.

Most Common Second-Life Applications

- Home and commercial energy storage

- Backup systems for solar and wind installations

- Grid balancing and peak shaving

- Portable industrial power units

Why second life matters:

- Extends battery life by 5–10 years

- Reduces the need for new mining

- Lowers the environmental footprint of EVs

- Helps stabilize renewable energy grids

Major automakers—including Nissan, BMW, and Tesla—already operate second-life programs, with more joining in as recycling technology becomes more mature.

Leading Lithium Recycling Companies in 2025

The rise of EVs has created a booming new sector: lithium recycling companies. Some of the global leaders include:

1. Redwood Materials (US)

Founded by former Tesla CTO JB Straubel, Redwood operates large-scale hydrometallurgical plants and partners with major automakers.

2. Li-Cycle (Canada/US)

Known for its “spoke and hub” model, allowing regional processing and centralized refining.

3. Ascend Elements (US)

Specializes in producing high-quality cathode materials directly from black mass.

4. Northvolt (EU)

Operates Europe’s largest battery recycling facility, with strong commitments to closed-loop production.

5. CATL & GEM (China)

Asian market leaders with huge recycling capacities and government-backed infrastructure.

These companies are crucial for achieving a circular battery economy.

Environmental Benefits-And Ethical Considerations

Environmental Benefits

- Reduced mining for lithium, cobalt, and nickel

- Lower CO₂ emissions compared to primary extraction

- Less toxic waste in landfills

- Cleaner battery supply chains

Ethical Considerations

Consumers are increasingly asking:

- Where do recycled minerals go?

- Are companies truly transparent?

- Is second-life repurposing safe?

- How are workers protected in recycling facilities?

As of 2025, regulations in the EU and US require companies to report recycling rates, but transparency still varies.

The Future of EV Battery Recycling (2025–2030)

Here’s what experts expect:

Recycling rates will rise from ~15–20% today to over 60% by 2030

Driven by regulation and technological progress.

Second-life batteries will become mainstream in renewable energy

Making EVs a key part of global decarbonization.

Recycled lithium will compete with mined lithium on price

Reducing dependence on global mining operations.

Fully closed-loop battery manufacturing will become standard

Companies that fail to adapt will lose market competitiveness.

Conclusion: Yes, EV Batteries Are Recycled-But the Industry Is Still Evolving

In 2025, the path of an EV battery is more transparent than ever, yet still somewhat fragmented. While true end-of-life recycling is absolutely happening, a significant share of batteries first enter second-life applications, extending their usefulness and reducing environmental strain.